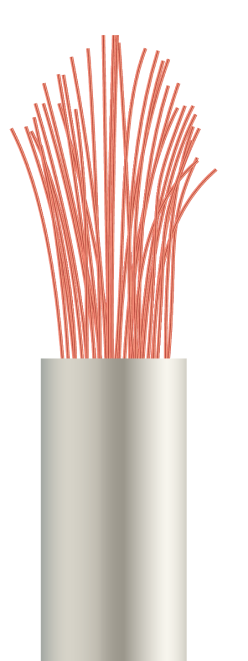

At Wiretech, we understand that every partner has unique requirements. That’s why we tailor our production to suit your processes and design, ensuring a seamless fit. From the initial steps to selecting the ideal grade, we support your daily operations and new product introductions (NPIs). Count on our expertise, development support, and material know-how from the early design stages to achieve outstanding results.

Our team of technology and material experts boasts 40 years of experience working in a multinational environment, specializing in processing tungsten for diverse application fields. From medical to electronics, welding to automotive, there are no limitations when it comes to tungsten wire. We fine-tune its properties to suit any application field, providing tailored solutions for our partners.

At Wiretech, we pride ourselves on delivering uncompromising quality and high-capacity in tungsten wire manufacturing. With decades of experience and in-house developed processes, we guarantee exceptional products right from the heart of the EU. Our wire production capabilities meet the highest industry standards, including FDA requirements, ensuring the utmost reliability for your applications.

Choose WireTech as your trusted partner for high-quality tungsten wire solutions! Fill out the form below to discuss your requirements!

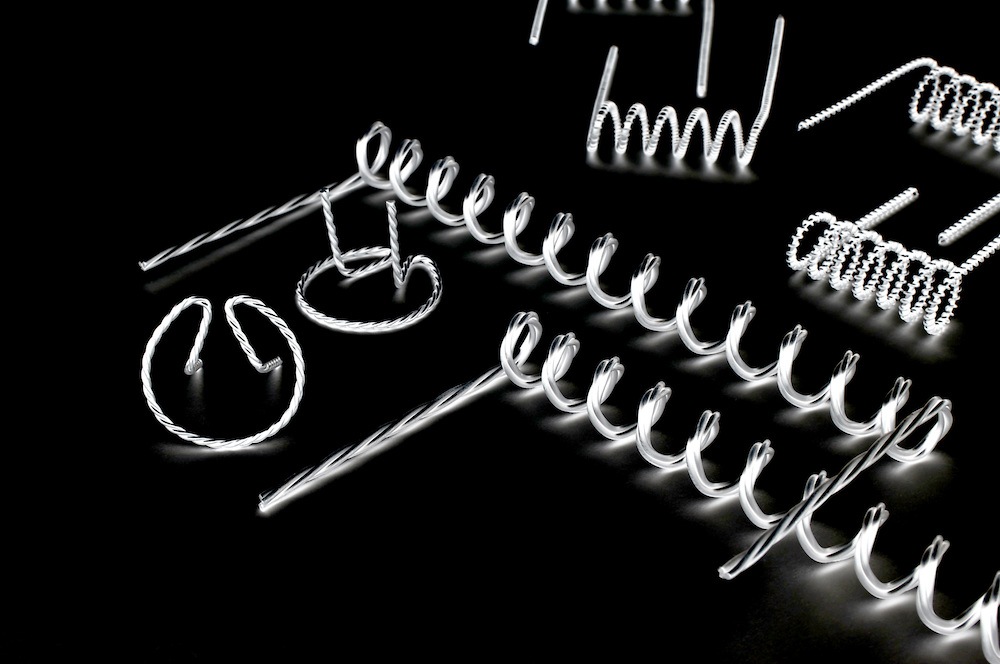

Our tungsten wire offers a range of mechanical properties and finishes, allowing you to choose exactly what you need. Whether you require black as drawn or polished clean tungsten wire, we have you covered. With custom-made mechanical properties and the availability of BAD and EP versions, you can achieve optimal performance in your final application.

3370°C (6100°F)

Tungsten has the highest melting point among metals at 3370°C (6100°F)

2965 MPa (430000psi)

Tungsten has the highest tensile strength amongst non-alloyed metals at 2965 MPa (430000psi)*

4,5ɑ (μm/m°K)

Tungsten has the lowest thermal expansion coefficient amongst metals at 4,5ɑ (μm/m°K)

3370°C (6100°F)

Tungsten has the highest melting point among metals at 3370°C (6100°F)

2965 MPa (430000psi)

Tungsten has the highest tensile strength amongst non-alloyed metals at 2965 MPa (430000psi)*

4,5ɑ (μm/m°K)

Tungsten has the lowest thermal expansion coefficient amongst metals at 4,5ɑ (μm/m°K)

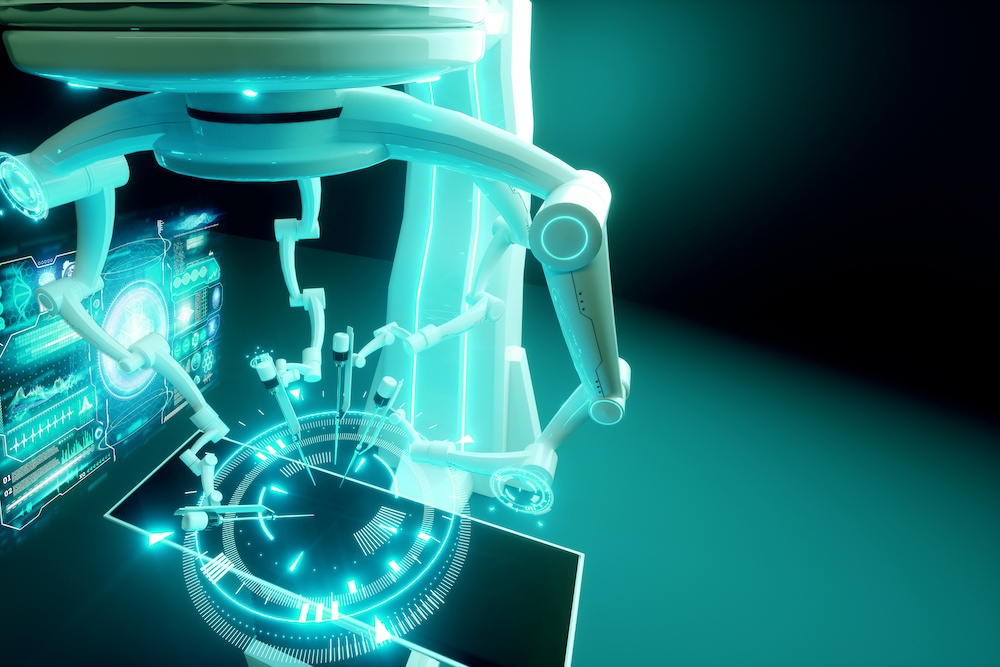

The medical sector demands the highest quality standards, and Wiretech excels in meeting and exceeding them. Our track record and tradition of developing professional processes make us exceptionally suitable for adapting to these stringent requirements. With in-house professional engineering knowledge and extensive manufacturing capabilities, we position ourselves as one of the most competitive and flexible players in the market for medical technology manufacturing projects.

For instruments used in surgical robotics, we offer tungsten wire with custom mechanical properties and finishes. Our wire’s special surface design and composition ensure high mechanical and chemical stress resistance, making it ideal for surgical robots. Rely on our experience and expertise to develop products tailored to your needs.

Wiretech fully adapts to emerging customer needs in the field of electrosurgery. We offer unique and customizable solutions, supporting developments from the early stage of new product introductions. Through multiple iterations and careful testing, we define the ideal material parameters for your application.

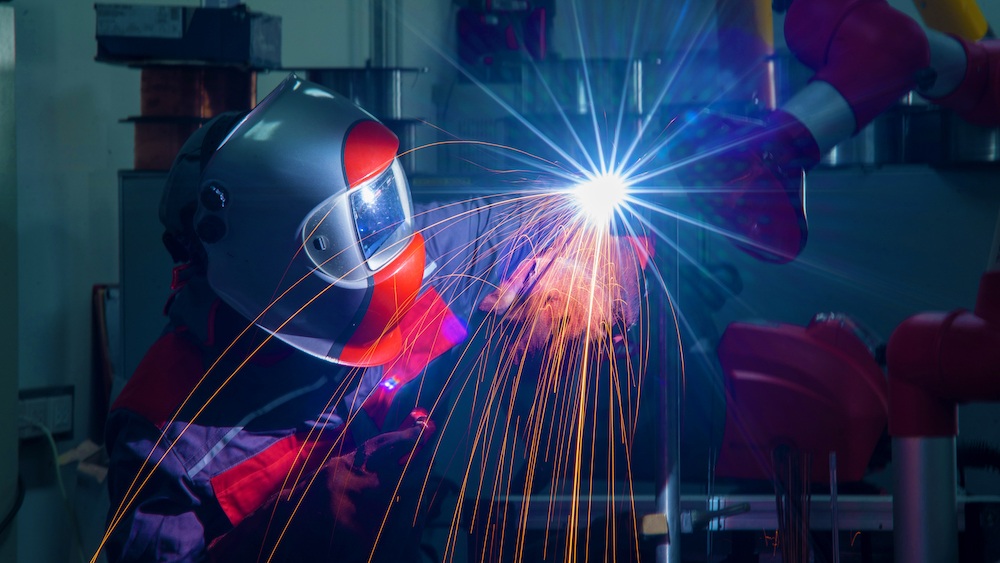

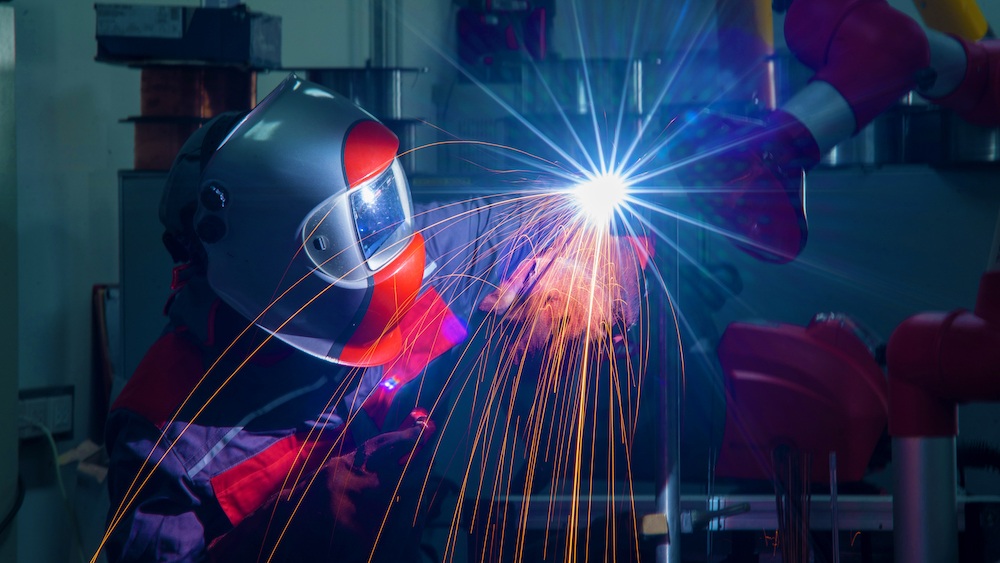

Our tungsten electrodes guarantee smooth and slag-free welding seams. Whether for EDM or TIG welding, we produce tungsten wires/pins according to your defined dimensions and surface quality.

Utilize our tungsten wires as heaters for vacuum metalizing technologies like PVD. They create thin films for various products, including Christmas baubles, reflection caps, and special machine parts, ensuring a shiny and durable coating.

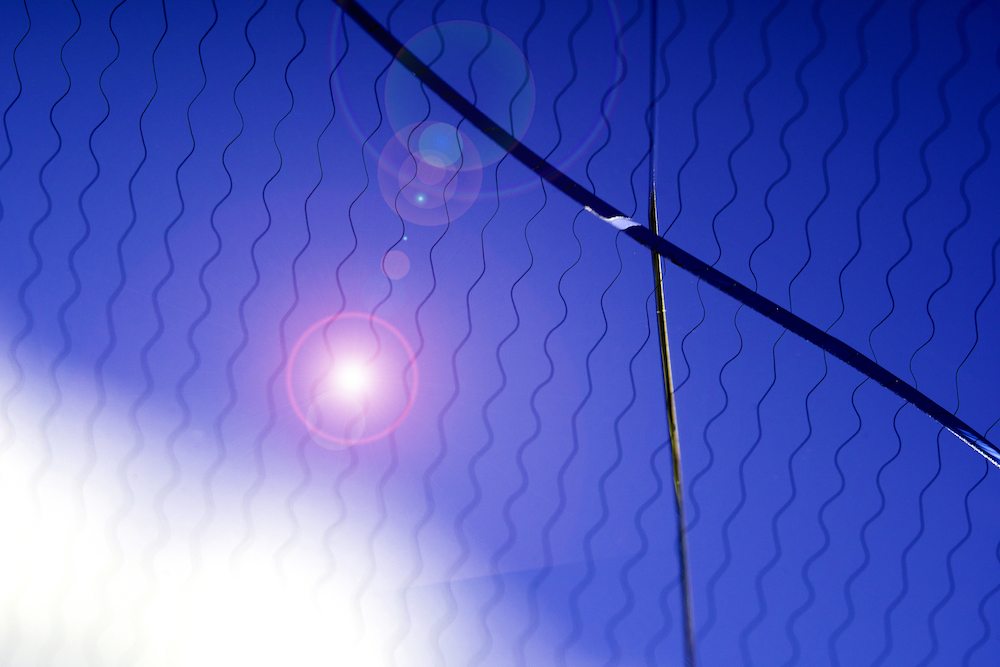

Our tungsten wire components excel in heated windshields for vehicles. With stable resistance, minimal visibility, and energy-efficient performance, our tungsten wire guarantees an enhanced driving experience.

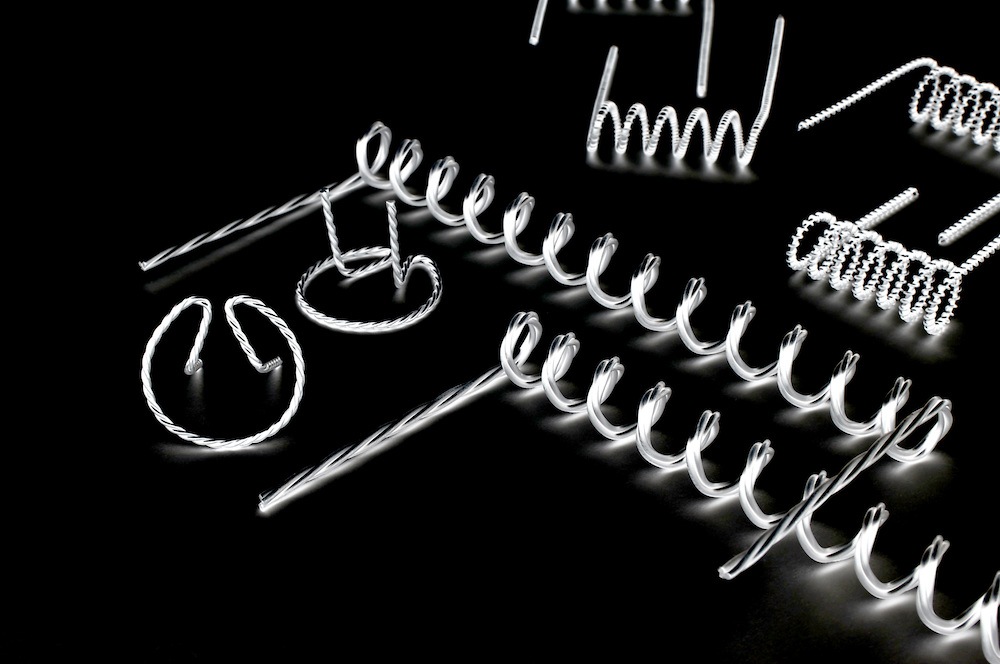

We provide high-quality tungsten filament components for light bulbs, catering to traditional, CMH, and horticulture lamps. Benefit from our knowledge and commitment to meeting the most rigorous standards.

Our tungsten electrodes guarantee smooth and slag-free welding seams. Whether for EDM or TIG welding, we produce tungsten wires/pins according to your defined dimensions and surface quality.

Utilize our tungsten wires as heaters for vacuum metalizing technologies like PVD. They create thin films for various products, including Christmas baubles, reflection caps, and special machine parts, ensuring a shiny and durable coating.

We provide high-quality tungsten filament components for light bulbs, catering to traditional, CMH, and horticulture lamps. Benefit from our knowledge and commitment to meeting the most rigorous standards.

Our tungsten wire is utilized in thermal applications, defense, aerospace, fishing, music, laboratory supplies, microscopy, and microstructural analysis.

Whether you require stable measurement performance over 2000°C, surface coatings for antennas and deployable mesh reflectors, or tungsten wires for fishing tackles and musical strings, we have the expertise to deliver exceptional results.

Chief Revenue Officer

Chief Revenue Officer with 20+ year experience in foreign trade, imports and exports of industrial products, specialized in non-ferrous drawn semi-products and in the foundry industry. Successfully managed sales and finance teams both in multinational and SME environment. Beside business development bringing proven expertise in financial control and management of multiple companies for the last 10 years. In business I am committed to partnerships with mutual interests and always targeting win-win situations.

Operations Director

Operations Director with working knowledge in wide range of manufacturing areas (ceramics, electronic assembly, powder metallurgy, wire drawing and more. Served 15 years in multinational environment, from engineer level to multi plan manager role. Active in strategy and business development. Bringing also strong engineering knowledge in materials science with academic background.

R&D Manager

karoly.sebok@wiretech.hu

+36304751399

R&D Manager

Materials Manager, owning all logistics, planning, warehousing and raw material related topics. 30+ years of experience in tungsten industry from different roles in operation, materials and technology. Physicist who has a great combination of detailed theoretical and wide practical knowledge. Bringing also analytical mindset to the team.

Production Leader

laszlojozsef.nagy@wiretech.hu

+36704003113

Production Leader

Production Leader with 10+ years focused experience on tungsten and molybdenum wire production using drawing, rolling, electrochemical technologies. Expert in product and technology development, designing our products according customer needs. Measurement system developer which used in our production to assure uncompromised quality.

Quality Manager

ildiko.baloghne@wiretech.hu

+36304751401

Quality Manager

Quality Manager with Six Sigma Black Belt and LEAN Champion certificates. Assuring process and product quality according to the highest standards. Always keeping in focus customer care and relations. Actively supporting new product introductions, root cause analysis, defining corrective actions on both our and our clients’ end. Quality system (ISO 9001) and technology owner for full production. Continuously improving our systems.

EHS Manager

EHS Manager

EHS Manager, passionate about all subjects of Environment Health and Safety. From global leadership role bringing systematic vision to our operation. Managing cooperation with authorities, subcontractors, keeping in one hand all EHS related topics. Expert in management system development like ISO 14001 and 45001. Successfully managing a multi organizational team, as contractor strongly supporting us on a daily level.

Choose WireTech as your trusted partner for high-quality tungsten wire solutions! Fill out the form below to discuss your requirements!

Copyright 2023 Wiretech